Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: Gamma Gas

Usage: Nitrogen

Purpose: Gas Manufacturing

Application Fields: Petroleum

Noise Level: Low

Machine Size: Large

Certification: CSA

Technology: Pressure Swing Adsorption

Packaging: Plywood package

Productivity: 20 pcs per month

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 20 pcs per month

Certificate: CE certification

Port: Qingdao,Tianjin,Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,FCA,CPT,CIP

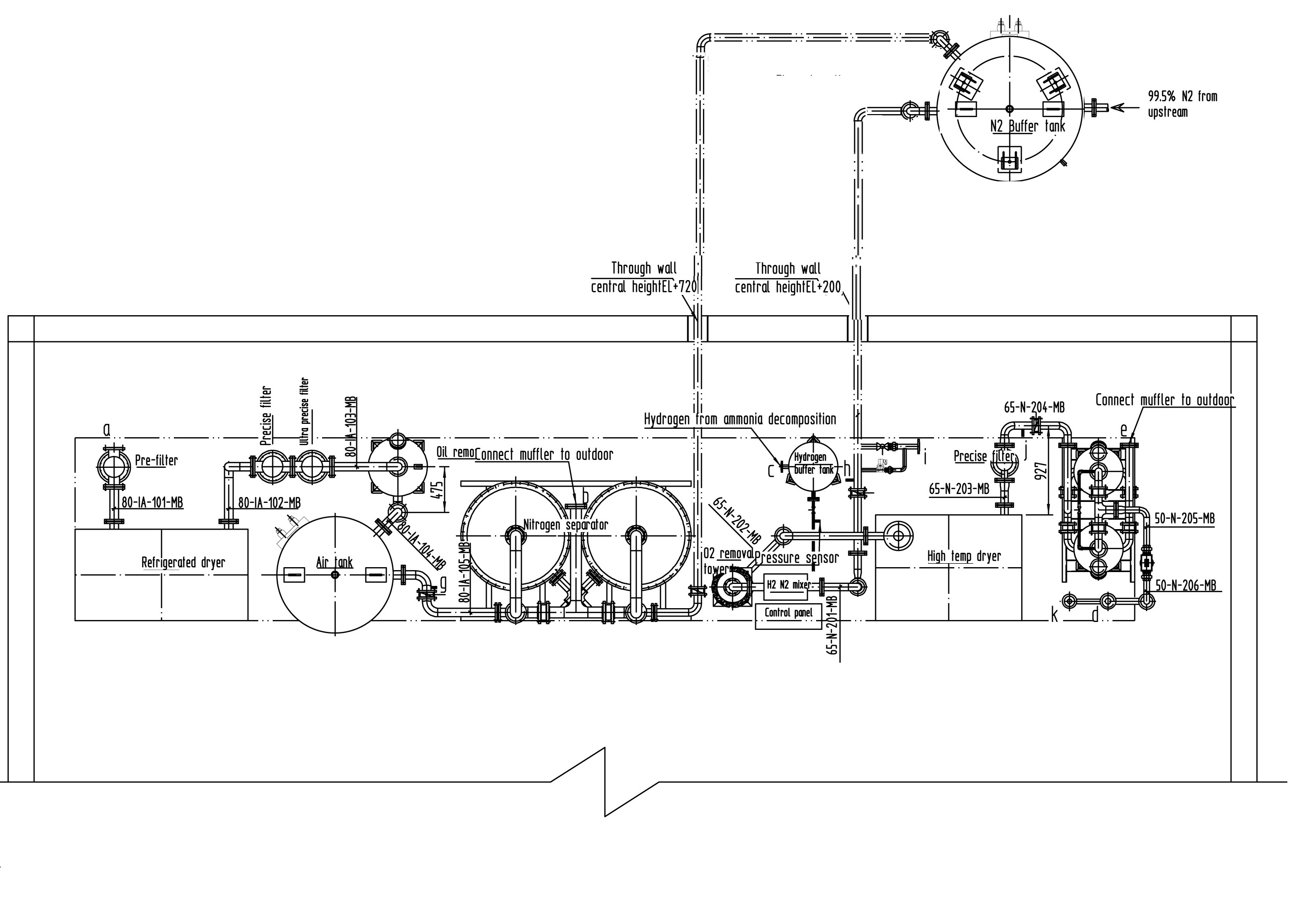

Gamma high purity automatic operation onsite Nitrogen Generation System can get super high purity nitrogen up to 99.9999%. There are two ways to get this high purity. One is using one step. The other is use lower purity nitrogen, then use one nitrogen purifier. With one step process, the compressed air consumption is big, which makes operation cost high. In order to save long time operation cost, two steps are often used. It consists of one 99.5% or 99.9% purity Nitrogen Generator and one nitrogen purifier.

The 99.5% or 99.9% purity nitrogen generator is air sourced by Screw Air Compressor, use PSA technology to get desired nitrogen. It has related air treatment part such as dryer, filters, etc. The nitrogen purifier is a machine to mix hydrogen and the produced nitrogen, react with the help of catalyst. With the function of catalyst, hydrogen and oxygen react under normal temperature, get water. In this way, oxygen within Nitrogen Gas is futher removed. Chemical formula is as below:

2H2+O2==2H2O+Q

During the process of removing oxygen, water will be generated. In order to reduce the dew point of produced nitrogen, there are cooler, Adsorption Dryer, filtration dust removal devices in the system, used to remove water, dust, etc to get high purity clean nitrogen.

High purity onsite Nitrogen Generation system principle

This High Purity Nitrogen Generator uses PSA (Pressure Swing Adsorption) technology, use CMS(Carbon molecular sieve) as adsorbent to separate nitrogen from air.

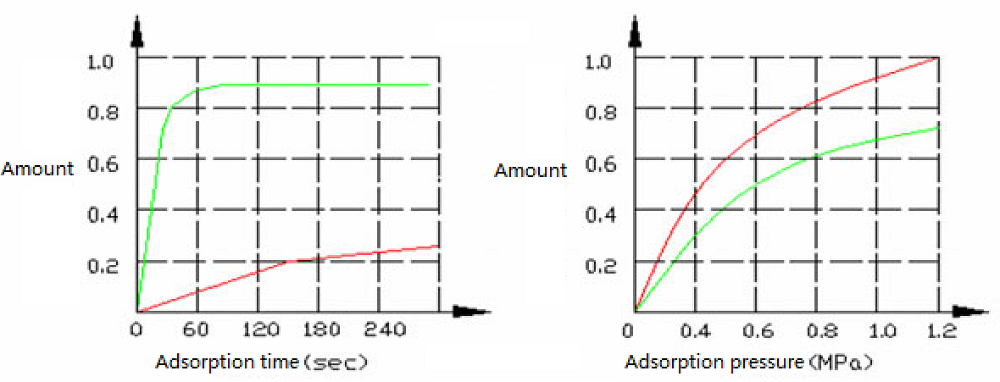

PSA: It is short term for Pressure Swing Adsorption. Normally, with higher air pressure, the higher adsorption amount of adsorbent can be obtained. Therefore use the periodically up and down of gas pressure, adsorb with pressure rise, desorb with pressure drop, realizing constant gas separation. This is the circulation process of PSA.

As this plant is highly automatically operated, it can also produce high purity up to 99.9999%. Therefore Gamma this high purity automatic operatoin onsite nitrogen plant is widely used by many customers who need high purity nitrogen.

High Purity Nitrogen Generator Technical Specification:

Nitrogen flow rate: 5-3000 Nm3/Hr

Nitrogen purity: 95-99.9999%

Product Categories : Skid Nitrogen Generator > High Purity Nitrogen Generator

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.