Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: Gamma Gas

Usage: Nitrogen

Purpose: Gas Manufacturing

Application Fields: Pharmaceutical

Noise Level: Low

Machine Size: Large

Condition: New

Certification: RoHS

Packaging: Plywood box

Productivity: 20 pcs per month

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 20 pcs per month

Certificate: CE certification

Port: Tianjin,Qingdao,Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CIF

Gamma Gas CMS PSA Gas Nitrogen Generator is one kind of High Purity Nitrogen Generator use CMS(Carbon molecular sieve) as adsorption material to separate oxygen and nitrogen. With PSA(pressure swing adsorption) technology, when pressure rise, the oxygen from air can be adsorbed inside the CMS, while nitrogen could not be adsorbed, so the nitrogen goes out to be collected as production gas for varous industrial applications.

High purity nitrogen generator is gas nitrogen generator, in the product gas, the nitrogen purity can be as high as 99.999% even 99.9999%. To achieve high nitrogen purity, the raw material, compressed air consumption is higher than achieving low purity nitrogen.

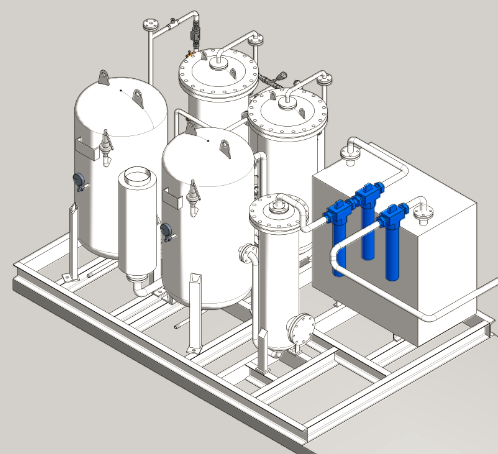

Structure of high purity nitrogen generator is like this:

Gamma Quality Industrial Gaseous Nitrogen Equipment Features

Energy Saving

For nitrogen generator, during operation, the only consumption is compressed air. So maintaining same nitrogen flow rate and purity, with less compressed air consumption, the whole system consumes less electricity for the Air Compressor. As nitrogen generator is designed for 24 hours non-stop operation, machines with better energy-saving performance reduces machine lifetime cycle investment.

Energy saving -Air flow guidance hole plates

Making most use of compressed air inside the adsorption tower is a good way to achieve energy-saving. Gamma Nitrogen Generators are equipped with air flow guidance hole plate distributor at both sides of the tower. This well designed gas distributor has multiple layer structure and scientific hole arrangement, it makes compressed air very evenly pass through adsorption tower, greatly reduce dead space and invalid space, remarkable improve molecular sieve utilization ratio and compressed air source utilization ratio.

Quality Industrial Gaseous Nitrogen Equipment principle:

High purity nitrogen generator photos

Quality Industrial Gaseous Nitrogen Equipment Delivery

Product Categories : Skid Nitrogen Generator > High Purity Nitrogen Generator

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.