Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: POMH93-10-150

Usage: Oxygen

Purpose: Gas Manufacturing

Parts: Gas Tank

Application Fields: Medical

Noise Level: Ultra Low

Machine Size: Medium

Condition: New

Certification: ISO

Packaging: Plywood box

Transportation: Ocean

Port: Qingdao,Tianjin,Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

Product details

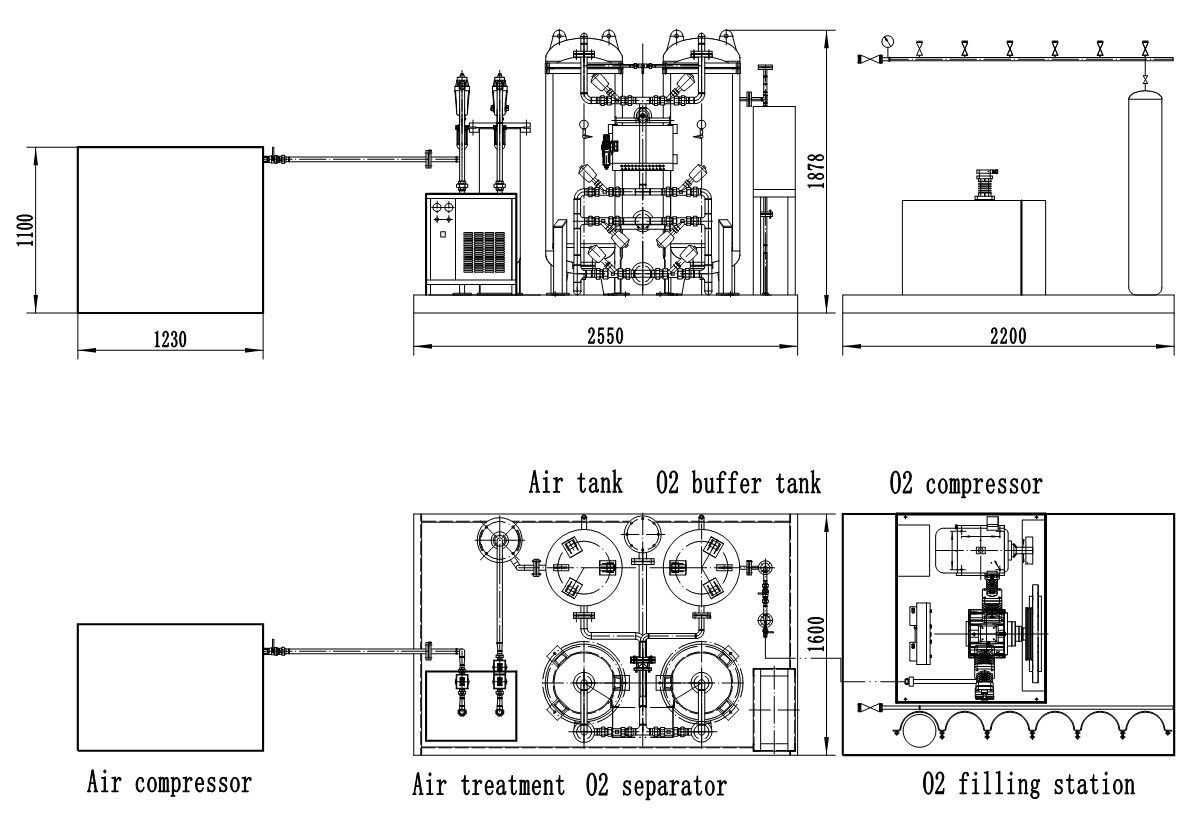

This system uses one Screw Air Compressor to provide compressed air for whole system meeting following requirement:

FAD capacity: ≥2.2 m³/min (This data is based on 1000m altitude, 45℃max temperature)

Discharge pressure: 7.5 barg

Discharge oil content:≤3ppm

Air treatment part

This air treatment part consists of one front filter, one refrigerated dryer, two post filters plus one activated carbon oil remover. At the outlet of air treatment part, the compressed air meets the following specification:

Capacity:3.0 m³/min

Atmospheric pressure dew point: ≤-20℃

Oil content: ≤0.003mg/m3

Treated compressed air enters air tank

Air tank

Treated compressed air is stored in an air tank, providing the big amount compressed air during oxygen separator two towers switch, reducing gas flow fluctuation when passing through air treatment part, optimize air treatment effect. Air tank specification is as below:

Volume:0.5 m³

Working pressure:8.0 barg

Material: Carbon steel

Safety valve, pressure meter, blow-down valve,etc parts are included.

Oxygen separator

This system uses PSA(pressure swing adsorption) technology, two adsorption towers alternatively work, constantly separate oxygen from air. Main oxygen specification is as below:

Flow rate :10 Nm3/hr(20℃,101.3 kPa)

Oxygen purity: ≥93%

Dew point : ≤-45℃

Oxygen buffer tank

Oxygen coming from oxygen separator is buffered and effectively mixed in oxygen buffer tank, ensuring the stability of oxygen pressure, purity and flow rate. It also provides blowing back oxygen for fast pressure increasing during two adsorption tower operation switch, further improve oxygen production ratio. At the outlet, there are flow, pressure and purity test instruments, realize oxygen real time monitoring. Oxygen buffer tank parameter is as below:

Volume:0.5 m³

Working pressure:8.0 barg

Material: Carbon steel

Safety valve, pressure meter, blow-down valve,etc parts are included.

Oxygen treatment part

The produced oxygen then enters one oxygen treatment part which has coalescing, microbiological filters to achieve clean and hygiene oxygen.

In order to achieve oxygen pressure 150 barg, one oxygen compressor is equipped, which parameter is as below:

Capacity:10 Nm3/hr(20℃,101.3 kPa)

Inlet oxygen pressure::5.0 barg

Outlet oxygen pressure:150.0 barg

Oxygen filling station

In order to fill oxygen into cylinders, one oxygen filling station is supplied with 2 x 3, totally 6 filling positions, suitable for filling cylinders with CGA 540 valve.

Product Categories : Oxygen Generator

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.