Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: PNM59-300

Brand: Gamma

Usage: Nitrogen

Purpose: Gas separation

Application Fields: Petroleum

Noise Level: Low

Machine Size: Medium

Condition: New

Certification: CE

Technology: PSA Pressure Swing Adsorption

Packaging: Plywood packing

Productivity: 20 pcs per month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 20 pcs per month

Certificate: CE certification

HS Code: 84213990

Port: Qingdao,Tianjin,Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,FCA,CPT,CIP

PSA nitrogen production

Pressure swing adsorption gas separation technology is an important branch of non-cryogenic gas separation technology. PSA uses air as the raw material and Carbon molecular sieve as the adsorbent. Using the principle of pressure swing adsorption, the selective adsorption of O2 and N2 by carbon molecular sieve is used to achieve the separation of oxygen and nitrogen to obtain nitrogen. Compared with cryogenic nitrogen production, PSA nitrogen production has significant characteristics. Adsorption is performed at normal temperature without involving adiabatic problems. The process is simple, the device is compact, the operation and maintenance are simple, the startup is fast, and the gas production is fast (15 ~ 30min). The nitrogen purity of the product can be arbitrarily adjusted according to process requirements, and it has obvious advantages for hot-dip galvanizing that requires continuous supply of protective gas. Compressed air is used as the raw material for nitrogen production. Because piston air compressors are noisy and need frequent maintenance, screw air compressors should be used. Carbon molecular sieve is the key of Nitrogen Generator. The carbon molecular sieve we choose has excellent adsorption performance and the cost is not high. Valves are also the key to Nitrogen Generators. They require fast switching speeds, good airtightness, and long life. Generally, the valve switching life is required to be more than one million times. In fact, our valves can be used for several years and are very reliable. The structure of the adsorption tower (including the diameter-to-height ratio), air distribution, and the way of packing and compacting the carbon molecular sieve also greatly affect the performance of the nitrogen generator. The compacting of the carbon molecular sieve and the control of the gas flow rate are very important, otherwise frequent pressure changes in the adsorption tower will cause the carbon molecular sieve to move, wear quickly and become powder and useless. The valve switching is automatically controlled by PLC programmable controller, and the working cycle can be adjusted according to the performance and process requirements of the carbon molecular sieve. In order to ensure the long-term continuous production of galvanized lines, the configuration of the nitrogen generators adopts the scheme of two uses and one preparation or one use and one preparation. Nitrogen purification device The protection gas for hot galvanizing requires high purity. A nitrogen purification device is equipped with a pressure swing adsorption nitrogen generator, which is catalyzed by hydrogenation. The method of oxygen and adsorption drying is simple and reliable, and the purification effect is good. It is easy to reduce the impurity oxygen in nitrogen to less than 1 ppm and the dew point to below -60°C. Its purity exceeds the cryogenic air separation. In order to meet the requirements of galvanized wire, the following optimization measures are taken: The nitrogen purification device uses a high-efficiency palladium catalyst, which can purify the nitrogen purity from 99.5% to more than 99.9999%. The nitrogen purification device adopts a hydrogenation catalytic deoxidation method. For the addition of hydrogen, low-pressure ammonia decomposition should be used, and the working pressure of nitrogen purification should be increased by 0.5 to 0.7MPa through hydrogen pressurization. Water vapor has a strong oxidizing property in the high temperature furnace, so the moisture in the protective gas should be fully removed. The nitrogen purification device is equipped with trace oxygen, trace water, and nitrogen-to-hydrogen analyzers to monitor nitrogen purity online. In addition, the valve switching and regeneration temperature control of the entire system can be automatically operated using a PLC programmable controller.

Techincal principle of PSA nitrogen plant

PSA Standard Nitrogen Generator is a machine producing nitrogen by separating nitrogen from air. It adopts the principle of PSA(pressure swing adsorption).

Pressure swing adsorption processes rely on the fact that under pressure, gases tend to be attracted to solid surfaces, or "adsorbed". The higher the pressure, the more gas is adsorbed; when the pressure is reduced, the gas is released, or desorbed.

Nitrogen plant process flow

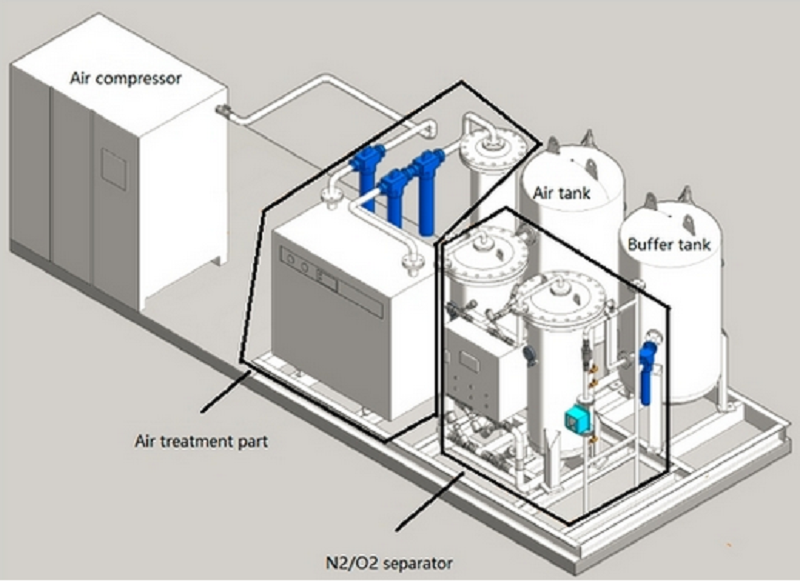

The main process flow of PSA skid nitrogen plant is as following:

Air Compressor suction air from atmosphere,then the compressed air enters one air treatment part to get rid of dust,water, dust,etc, achieving clean and dry compressed air. This air treatment part mainly consists of three filters, one Refrigerant Dryer and one activated carbon oil remover. After treatment, the compressed air enters one air tank to make air stable. Then the compressed air enters PSA nitrogen/oxygen separator. After passing through this nitrogen/oxygen separator part, nitrogen is collected. The produced nitrogen enters one nitrogen buffer tank. At the outlet of nitrogen buffer tank, stable and qualified nitrogen is sent to using point.

PSA Nitrogen Plant Technical Specification

Flow rate: 5-3000 Nm3/hr

Purity: 95-99.9999%

Outlet perssure: 5-200 bars(72.5-2900 psi)

PSA Nitrogen Plant Structure

This standard nitrogen generator consists of air compressor, air treatment part, air tank, nitrogen separator part and nitrogen buffer tank.

Here are some different flow standard nitrogen generator for reference:

Product Categories : Skid Nitrogen Generator > Standard Nitrogen Generator

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.