Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: PNM-HG

Brand: Gamma Gas

Usage: Nitrogen

Purpose: Gas Manufacturing

Application Fields: Petroleum

Noise Level: Low

Machine Size: Large

Condition: New

Certification: CE

Packaging: Container

Productivity: 20 pcs per month

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 20 pcs per month

Certificate: CE certification

Port: Qingdao,Tianjin,Shanghai

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF

2018 new 95% Membrane Nitrogen Generator

Model no: PNM-HG Structure: Skid Nitrogen purity: 90-99.999% Flow rate: 1-3000 Nm3/hr/105944 SCFH Nitrogen pressure: 1-300 bars/4351psi Function: Producing Nitrogen Gas with designed flow rate, purity and outlet pressure Features: 1 Skid installation, easy transportation and easy installation; 2 Intelligent control, fully automatic operation, can be remote started; 3 Nitrogen flow rate, purity online monitoring and remote display; 4 Nitrogen flow rate, purity adjustable; 5 High reliability, no purity flow rate drop after years operation.

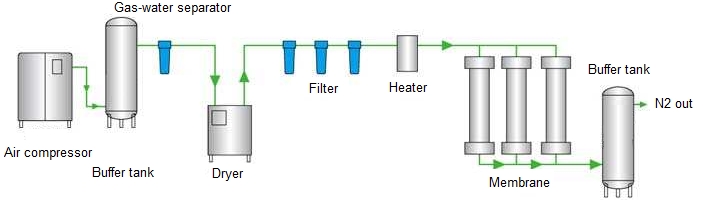

600 Nm3/hr, 95% Purity, 350 Bars Membrane Nitrogen Generator is one kind of nitrogen generator using membrane technology, the process flow of Gamma membrane nitrogen generator is mainly as follows: Ambient air is compressed by oil-injected screw air compressors,which is powered by diesel engine power generator, then enters after cooler to cool the compressed air, then enters air tank, to air treatment system. This air treatment system has Air Filter to filtrate, activated carbon filter to remove oil and it has air temperature adjustment device. After these treatment, dry, clean, constant temperature compressed air enters membrane nitrogen-oxygen separation system. The separated oxygen-rich air is discharged into atmosphere, nitrogen with desired purity is sent to nitrogen booster. After compress its pressure to desired requirement, then nitrogen is sent to using point.

Product Categories : Membrane Nitrogen Generator

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.