Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: Gamma Gas

Usage: Oxygen

Purpose: Gas Manufacturing

Application Fields: Chemical

Noise Level: Low

Machine Size: Medium

Condition: New

Certification: CSA

Packaging: Plywood Box

Transportation: Ocean,Land

Place of Origin: China

Port: Qingdao

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,FCA,CPT

Onsite PSA Oxygen Generation Machine Setup Cost is the key consideration for all customers need this kind of machine. Customer need first find out how many cubic meter per hour or SCFM, SCFH flow rate is suitable for their application. Also need to decide what oxygen purity is suitable. The higher purity requirement means higher investment cost. So it is important to find out the acceptable minimum purity requirement. With these information, the size of Oxygen Machine is decided.

When considering the cost of setup one Onsite PSA Oxygen Generation Machine, please consider the oxygen generation machine purchase cost and operation electricity consumption cost, also the yearly maintenance cost.

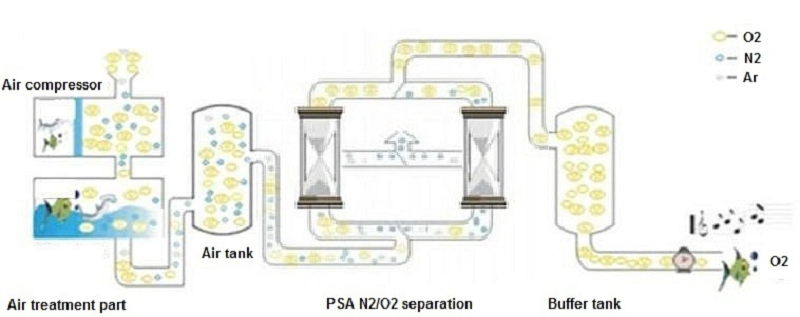

Onsite PSA Oxygen Generation Machine use PSA technology to separate oxygen from air. This Oxygen Generator has advantages of reliable operation. It is ideal replacement of cylinder oxygen supply. Gamma medical oxygen machine has advantage that after years operation, the oxygen purity and oxygen flow rate do not drop.

Oxygen machine producing oxygen is achieved by molecular sieve. Molecular sieve is a kind of spherical granular adsorbent, the surface and the inner surface and the interior are filled with micro pores. Its groove characteristics enable the separation of oxygen and nitrogen. The separation of oxygen and nitrogen by molecular sieves is based on the small differences in the kinetic diameters of these two gases. The nitrogen molecule has a faster diffusion rate in the micro pores of the molecular sieve. Slow diffusion rate of oxygen then is collected as product gas.

Oxygen Machine Specification:

Flow rate: 5-300 Nm3/hr

Purity: 90-95%

Outlet pressure: 5- 10 bars

Product photos:

Onsite Oxygen Generation Machine Package and Delivery

Product Categories : Oxygen Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.